Silencer testing facility

Acoustics

Maximum efficiency and precision: Benefit from the Fraunhofer IBP silencer testing facility for your product development

Fraunhofer IBP’s silencer testing facility is a state-of-the-art installation for testing and optimizing silencers and aerodynamic components in accordance with DIN EN ISO 7235. Manufacturers benefit from precise measurements of insertion loss, sound power and pressure loss, which serve as a basis for developing efficient, high-performance products. The testing facility makes it possible to study and further develop innovative concepts under controlled conditions. The versatile design of the test tunnel allows it to be adapted to specific customer requirements, while the latest measuring equipment enables detailed acoustic analyses to be carried out. Strict noise control measures ensure that results are not affected by external noise, thus guaranteeing high measurement accuracy and reliability.

Working together with the Department of Acoustics at Fraunhofer IBP offers you decisive advantages. You can depend on us to conduct tests that comply with the relevant standards and to provide comprehensive support for your product development activities. Our expertise in silencer testing maximizes the acoustic performance and efficiency of your products. Precise analyses and targeted advice give you a competitive edge and strengthen the innovative power of your products.

How can we help? Find out more about our range of services now or send us an e-mail.

This is a modal window.

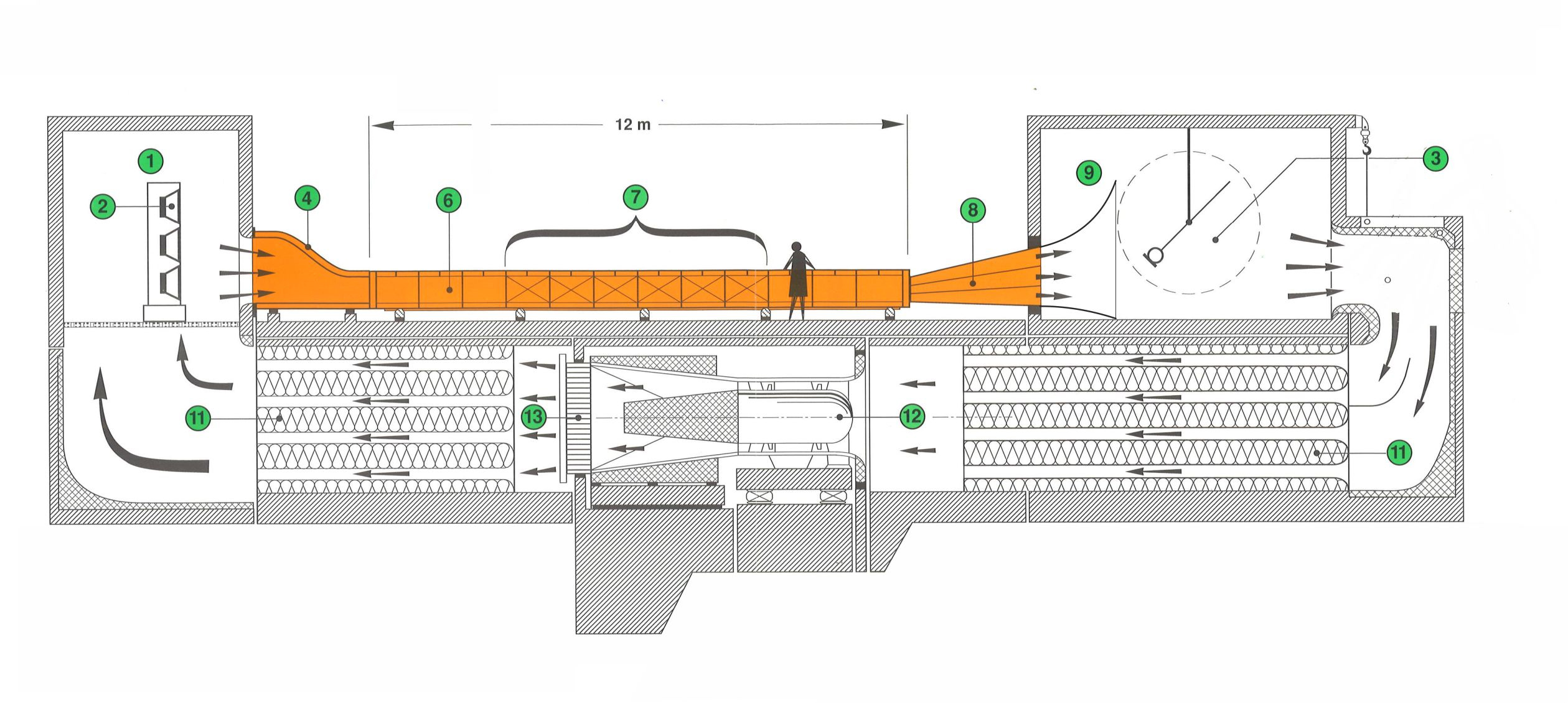

Sketch of the wind tunnel

Analyses in accordance with DIN EN ISO 7235

| Measured variables | - Sound power - Wind and flow noise - Insertion loss - Pressure loss |

| Norms | DIN EN ISO 7235 and DIN EN ISO 3741 |

| Test objects | - Silencers as splitters, splitter silencers of all kinds - Duct silencers (cross-talk sound attenuators, exhaust silencers, ship silencers, etc.) - Silencers in special designs - Ventilation components (filters, heat exchangers, etc.) - Façades, façade elements - Weather protection grilles - Fans - Other HVAC system components (filters, heat exchangers, grilles, dampers, etc.) |

Technical data of the silencer testing facility

| Rectangular test tunnel (L x H) | 12 m x 0,5 m |

| Width of rectangular test tunnel | 500 mm to 1300 mm (50 mm increments) Special structures possible |

| Round test tunnel (DN) | 400 mm 200 mm ≥ DN ≤ 800 mm standard measurement Other diameters in accordance with the standard |

| Fan | Volume flow ≤ 35 m³/s Pressure difference ≤ 2500 Pa |

| Max. size rectangular test tunnel (L x H | 6000 mm x 498 mm |

| Max. size round test tunnel | 6000 mm long, DN 1200 mm and 6 tons in weight |

| Measuring system | Wind tunnel with circumferential, closed air circulation |

More Information

- Freely adjustable flow rate

- Quiet, uniform flow

- Measurement of sound power in the receiving room outside the flow

- Stationary equipment for measuring dynamic and static pressure

- Sound source with uniform radiation (loudspeaker wall 2800 W)

- Compressed air and electrical power connection available

- Crane runway available for heavier and larger structures

- Duct silencer up to max. 6 tons dead weight

- Duct silencer up to max. 6 m length

- Special duct silencers (weight > 6 tons and length > 6 m) in-situ measuring technique