Ventilation systems in the home must fulfill more and more requirements. In order to meet both energy and sound insulation requirements, an ever-increasing proportion of ventilation concepts have to be designed with fan-assisted systems. A fan-assisted exhaust air system in accordance with DIN 1946-6 is comparatively inexpensive and easy to install. With this system, the exhaust air is removed by fans in the rooms and replaced passively by an inflow of fresh air from external air vents (EAV). However, due to the increasingly airtight construction of new buildings, an ever-higher volume flow is needed. The high air flow means that sound insulation requirements cannot always be met. This is often particularly a problem in (inner) cities.

SleepWindow

Project goals

The aim of the “SleepWindow” project is to develop a new, intelligent external air vent (EAV) for windows. This should ensure an airflow rate of 30 m³/h, offer a high level of comfort (draft-free), protection against driving rain and Class 4 sound insulation. Good sound insulation is achieved thanks to an intelligent control system that can recognize and categorize external noises. An FFT analysis is used to identify relevant noises and automatically close the EAV before the noise reaches a certain volume. Room humidity is also measured in order to comply with the ventilation requirements stated in DIN 1946-6. An innovative indirect air flow guidance system and a new polymer composite material (to be developed) will also ensure optimum sound insulation and a pleasant flow of air. Finally, an extremely small actuator with electronics and a self-sufficient energy supply is being developed. This means that the device can be integrated universally and attractively into all window systems without impairing the structural properties of the window and how it is manufactured.

Project results

The experts from the Acoustics department are carrying out the project together with INNOPERFORM GmbH and are responsible for the development of the automatic air control system to regulate the sound insulation of the new EAVs. To this end, relevant noise patterns are being studied and resolved in frequency and time using FFT logic. An algorithm that works via machine learning combined with pattern recognition is used to analyze the sounds and compare them with known ones. Depending on the sound, a signal can be issued to close the EAV. In addition, continuous noise pollution will be measured and, depending on the result, the EAV opened as required to optimize sound insulation and ventilation. The control system is supplemented by an additional system that detects people in the room and monitors the CO₂ content and humidity. In this way, the sound insulating effect can be switched off when the room is empty, for example.

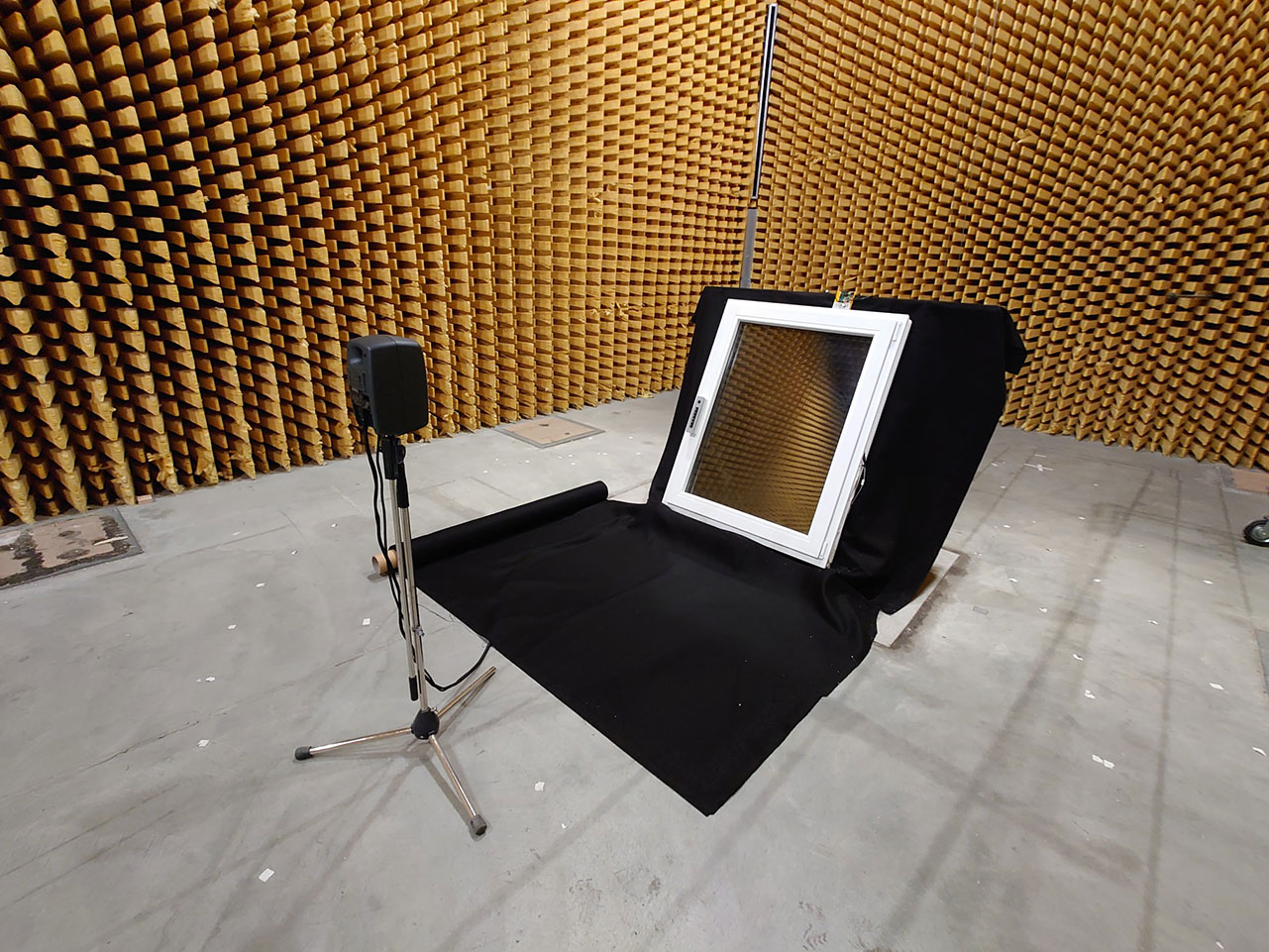

Our researchers are also investigating the aeroacoustic properties and standard sound level difference of the new EAV to prevent noise from being generated due to flow effects and to investigate the sound-absorbing properties. With this in mind, the air channel and the flow-relevant components, such as the shutter, are being examined and optimized in a wind tunnel with an external acoustic receiving room to determine the noise they generate through turbulences and stalls.

Project partners

- INNOPERFORM GmbH