Test method for determining airflow resistance

By determining airflow resistance in accordance with DIN EN ISO 9053-1, one of the most important characteristics of absorbers can be measured under standardized conditions: airflow resistance in proportion to length.

This parameter gives manufacturers and users of absorber materials valuable information about the material properties and can be used to create a calculation model (e.g. according to Delany Bazley or Johnson Champoux Allard). A major advantage of this is that the behavior of the absorber can be tested theoretically in different situations and configurations without the need for a physical test setup.

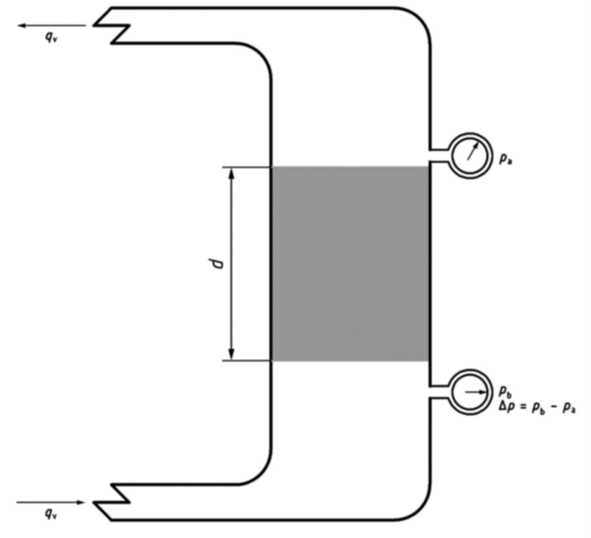

The measuring device generates a pressure difference in front of and behind the sample and relates it to the speed of the air flowing through the sample. The thicker the sample, the higher the airflow resistance. Airflow resistance in proportion to length is therefore used as a material characteristic; it is expressed in Pa·s/m² and has an optimal range. Airflow resistance is the only parameter that can be used to characterize thin materials such as fabrics and fleeces.

Would you like to learn more about determining airflow resistance or receive a measurement quote and advice on testing materials in accordance with DIN EN ISO 9053-1? Get in touch with us - we are looking forward to hearing from you.